Barcode Compliance labels

The Challenge: how to check if the Quality Grading of the Barcodes is correct?

When printing Data Matrix barcodes onto folding boxes using inkjet or laser printing directly at the packaging line achieving the required print quality can be challenging. An increased number of rejects and frequent machine stops can degrade overall packaging line efficiency. The barcode print quality is usually monitored by an in-line vision system, checking each printed barcode for the minimum mandated quality grade. This measurement cannot be validated as for example a checkweigher via calibration weights. Therefore, Vesdo developed in cooperation with leading Pharmaceutical companies a toolset that we made available to everybody who faces the same challenge:

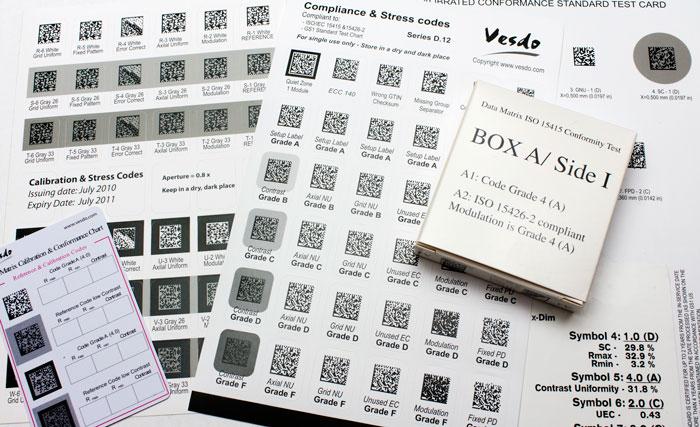

The Solution: Barcode Compliance Lables

Barcode Compliance Labels

Vesdo developed self-adhesive Compliance Labels that allow to validate the ISO compliance of any vision inspection system similar to calibration weights on your checkweigher. This is being achieved by simply applying the label onto the item to be inspected and place it in front of the in-line camera. The labels allow to selectively trigger six different ISO error channels for each quality grade ranging from A to F. The error channels are:

- Contrast

- Modulation

- Fixed Pattern Damage (FPD)

- Unused Error Correction (UEC)

- Axial Non-Uniformity (ANU)

- Grid Non-Uniformity (GNU)

Data Matrix Compliance

Vesdo does validate every barcode on the self adhesive label to ensure that they comply with the corresponding error level of every channel. The barcodes on Vesdo’s Labels comply with the relevant international standards:

- ISO/IEC 15415

- ISO/IEC 16022

- ISO/IEC 15426-2

- GS1 Calibrated Conformance Standard Test Char